Why are the slewing ring prices from different manufacturers so different? Many users will encounter such problems when purchasing slewing rings. What are the reasons for the huge differences in product prices among slewing bearing manufacturers? How can leaders reasonably explain why they are asked? Don’t worry, Xiao Bian will help you solve this problem today.

1. Cost difference caused by slewing ring raw materials

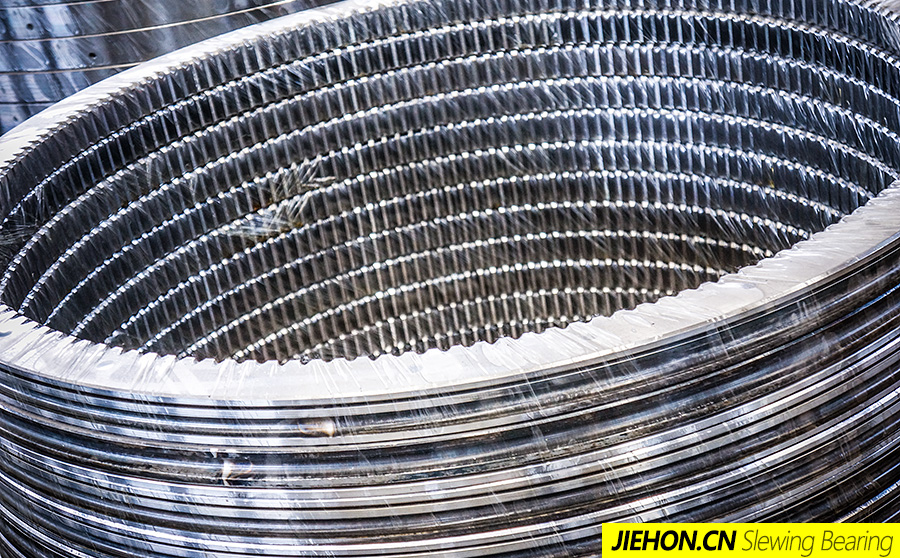

The main raw material of the slewing bearing is ring forgings, and the material is generally divided into 50Mn and 42Cr. The process is generally divided into normalizing and quenching. In this way, the slewing bearing raw materials can be divided into 50Mn normalizing material, 50Mn modified material, and 42Cr positive material. Fire material, 42Cr conditioning material four kinds of combinations. In terms of cost, 50Mn is cheaper than 42Cr, and the normalizing process is cheaper than the quenching process.

The production area of ring forgings varies, and the prices vary greatly. The ring forgings produced and processed by some family workshop-style small forging factories are much lower in price than formal forging plants. Their characteristics are that the forging quality, accuracy, and hardness of ring forgings are not stable enough, especially in small forging plants in some regions. The 45# steel was used instead of the 50Mn material. However, due to the lack of professional testing equipment for general users, its material composition was not known. As a result, the user chose a cheap quote without knowing the quality of the slewing bearing material.

Here, Xiaobian cautionfully reminds users that the slewing ring is a key rotating unit in mechanical equipment and its product quality can be said to be very important. With regard to the losses caused by some slewing bearing failures experienced by some users who have witnessed Xiaobian’s experience, the cost of the loss of the slewing bearing itself is not high, and at most one can replace it. However, the cost of removing and replacing the slewing ring is much higher than that of the slewing ring. The cost of the support itself. For example, before a foreign customer found out that we needed to purchase a slewing ring, we only knew after the exchange that the port crane we purchased could not be rotated, we needed to replace the slewing ring, and a set of slewing ring supports more than 10,000 yuan, but the entire ship was demolished. The cost of the delays caused by the project, which together add up to 40,000 or more, caused huge losses due to excessive losses and legal disputes with the HAECO suppliers. In fact, it was nothing more than that the HAECO manufacturers purchased unqualified products for the sake of cheapness. Slewing ring.

2. Difference in production costs caused by slewing bearing production efficiency

Different manufacturers have different production equipment and production experience, and natural production efficiency is also different. However, manufacturers with smaller scales may not necessarily be inefficient, and large-scale manufacturers may not necessarily be efficient. There is a question of marginal efficiency here. According to the company’s own market positioning, configuration of the corresponding production equipment, technical staff, combined with the best state, can achieve high efficiency operation of the company. In comparison, because of the management regulations, the production efficiency of the southern enterprises is generally higher than that of the northern enterprises. The domestic slewing bearing industry belts are: Dalian, Liaoning, Luoyang, Henan, Maanshan, Anhui, and Xuzhou, Jiangsu, compared to In the field of small slewing bearings, slewing ring suppliers in Xuzhou and Maanshan have higher management efficiency and lower management costs. The production equipment is basically digitized. If you need to purchase slewing rings with an outside diameter of 200-4000mm, Xiaobian recommends that you Can learn more about Xuzhou slewing bearing manufacturers, such as Xuzhou Jieheng Slewing Bearing Co., Ltd., are all very good slewing bearing manufacturers.

3. The difference in management costs caused by the scale strength of the slewing bearing plant

The larger the slewing bearing manufacturers, the lower their overall costs. Large-scale procurement and large-scale production will increase the production efficiency of slewing bearing manufacturers and reduce material costs. This point is relatively simple. When you choose a slewing bearing supplier, in addition to asking the manufacturer to issue business licenses and other information, you can generally ask the manufacturer to issue a factory land certificate, equipment list, and ISO9001 certification data to prove the scale and qualification of the company. Based on these documents, a simple calculation can give an idea of the scale of the slewing bearing manufacturer.

4, the price difference caused by the slewing bearing manufacturer’s market strategy

The above three points are only for the analysis of the cost of slewing ring, then the price also involves the slewing ring manufacturer’s positioning and marketing strategy in the market. Relatively mature slewing bearing manufacturers will choose conservative market strategies, prices will remain high, and some emerging slewing support manufacturers will choose offensive market strategies. Generally, prices will have certain advantages. This requires us to comprehensively analyze what the market strategy of the slewing bearing manufacturers is. For example, Xuzhou Jieheng slewing bearing, which is still in an offensive marketing strategy in the domestic market, enterprises in the completion of the construction of information platform, digital transformation of the production line, and vigorously improve the level of quality management, based on comprehensive strength to provide the most users around the world The cost-effective slewing bearing products have become the preferred slewing bearing supplier for many high-quality users in the domestic rotary market.

Having said so much, I hope that everyone can understand the slewing ring offer more deeply. We must not only choose the products that are cheap and beautiful, but also understand why the products provided by the company are cheap and beautiful, so that we can purchase real products. A cheap, beautiful slewing bearing product, not a poor quality product.

For more information, please continue to pay attention to Xuzhou Jieheng slewing bearing!