Slewing bearing manufacturers teach you to understand the slewing bearing inspection standards

After the user purchased the slewing ring, how to identify the quality of the slewing ring? What is the slewing bearing inspection standard? Today, Xuzhou Jieheng slewing bearing Xiaobian will take you to understand our slewing bearing inspection standards.

In general, inspecting slewing bearings requires the following 17 slewing bearing inspection standards:

1, slewing bearing gap inspection

The general slewing bearing design will specify the required axial and radial clearances. The produced slewing bearing must be checked for clearance data to see if the data is consistent with the design drawings. A gap that is too large or too small can cause problems, and only the gap that meets the design requirements is the most appropriate.

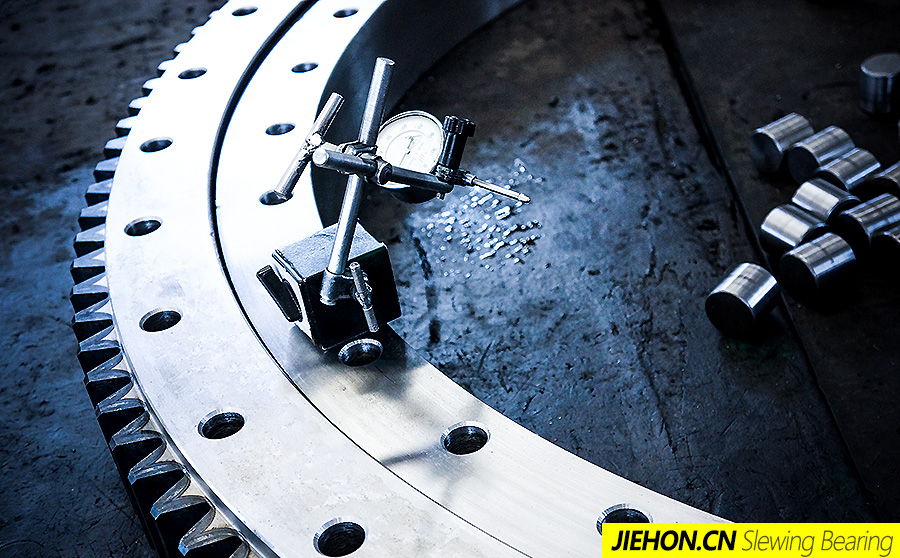

2, slewing bearing jump test

As with the clearance check, the slewing ring runout test is divided into an axial runout test and a radial runout test. Conditional users can use the test equipment to check the slewing bearing runout data to see if they meet product design requirements.

3, slewing bearing rotation flexibility test

The slewing ring is placed on a horizontal table and the slewing ring is turned. The general manpower or afterburner is basically normal. If you feel tight when turning, you can add grease and try again. During rotation, attention should be paid to whether or not the slewing bearing has abnormal sound. If it is the continuous rolling sound in the rolling of the steel ball, it is normal. If intermittent and sharp abnormal sounds occur, it is necessary to feed back the slewing bearing manufacturers immediately.

4, slewing bearing size inspection

Check whether the slewing bearing’s appearance size meets the design drawings, including the slewing ring’s inner diameter, outer diameter, and thickness, and check whether the appearance size data meets the requirements of the design drawings.

5, product number, label inspection

The slewing bearing of the regular factory will provide the slewing bearing product number, product label, and quality certificate to facilitate the user’s installation and preservation.

6, sealed installation inspection

The sealing of the slewing bearing needs strict inspection by the user. If the sealing strip is not firmly installed or has fallen off, it will cause foreign matter such as sand and gravel to enter the slewing bearing track, causing the failure of the slewing bearing to rotate or even track damage. The inspection method is to rotate the slewing bearing and check whether the sealing strip is firmly installed and whether the adhesive is stable.

7, appearance quality inspection

Although the appearance quality of the slewing bearing does not affect the normal use, it also absolutely represents the production management quality of a slewing bearing manufacturer. Well-formed slewing bearing manufacturers have strict slewing bearing production and inspection standards and procedures to ensure that each set of slewing bearings meets the best inspection requirements both in terms of appearance and intrinsic quality.

8, packaging inspection

Before the slewing bearing is packaged, it is necessary to apply a layer of anti-rust oil, then wrap the first layer with a waterproof membrane, wrap the second layer with a packaging tape, and wrap the third layer with a waterproof membrane. There are generally slewing bearings for special packaging and transportation needs, and custom packaging wooden boxes are also required.

In addition to mastering the above slewing bearing inspection standards, you can also require the slewing ring manufacturer to provide slewing bearing production inspection reports. In general, every slewing bearing of the manufacturer will keep an original slewing bearing inspection report to seal the raw product data. And management. With the inspection report, I believe you are even more comfortable with the slewing bearings you have purchased.

Thank you for your continued attention to Xuzhou Jieheng slewing bearings. If you have reprinted, please indicate from Xuzhou Jieheng Slewing Bearing Co., Ltd.